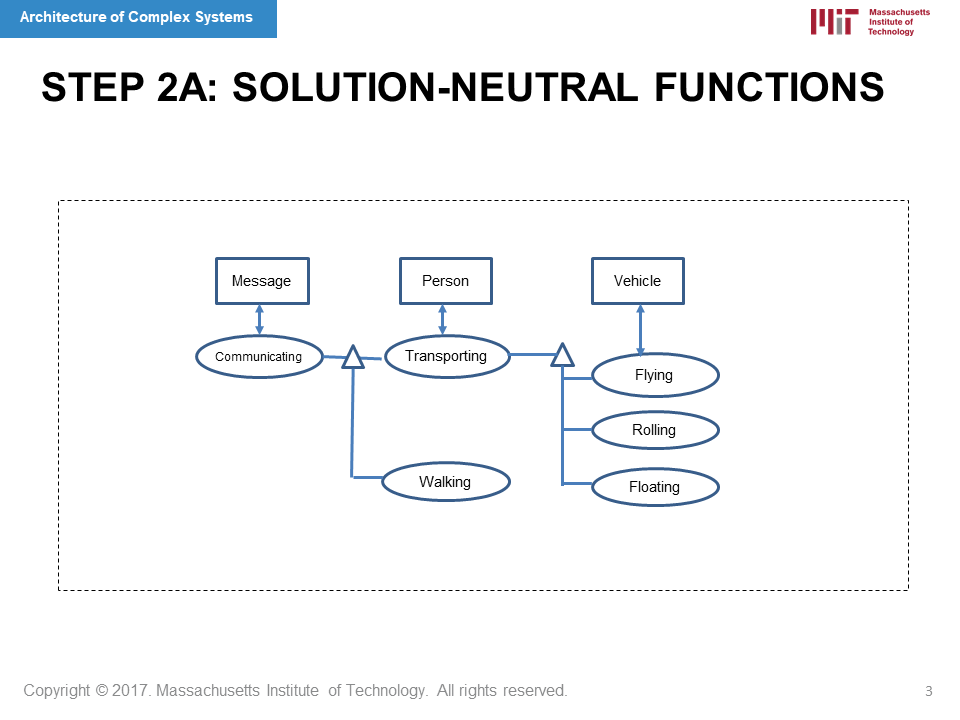

System Architecture is a conceptual design of an engineering system through the description of the entities that form the system, the relationships between those entities and the functions that results from them for the entire system. The complexity of a system is primarily determined by the architecture and complex systems such as in aerospace, infrastructure, computer software networks often result in emergent bahaviors for operators and/or users in the environment they exist.

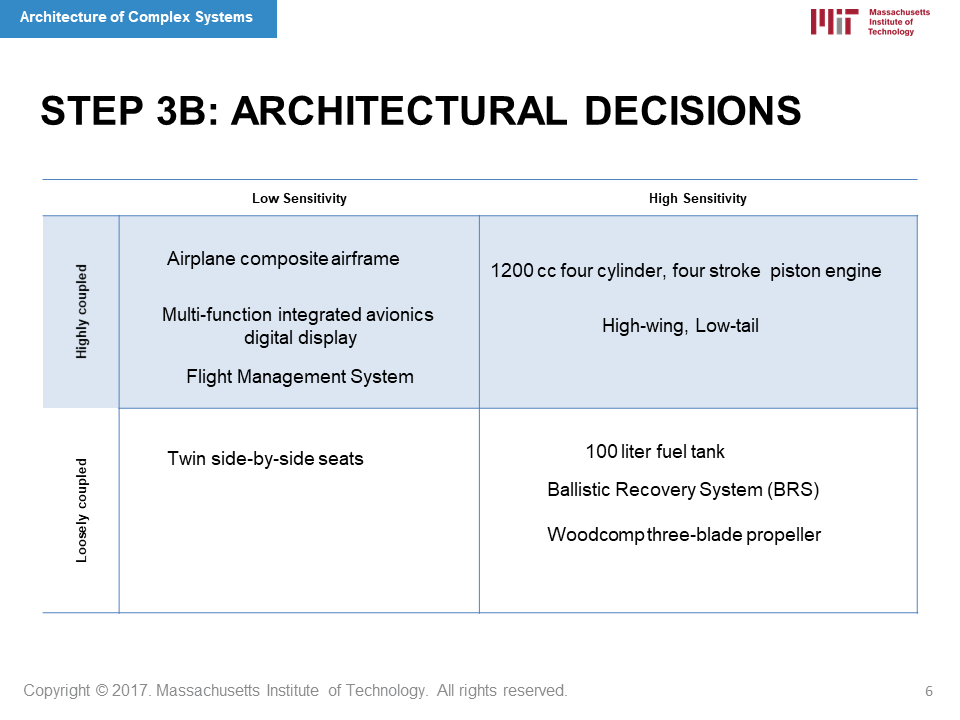

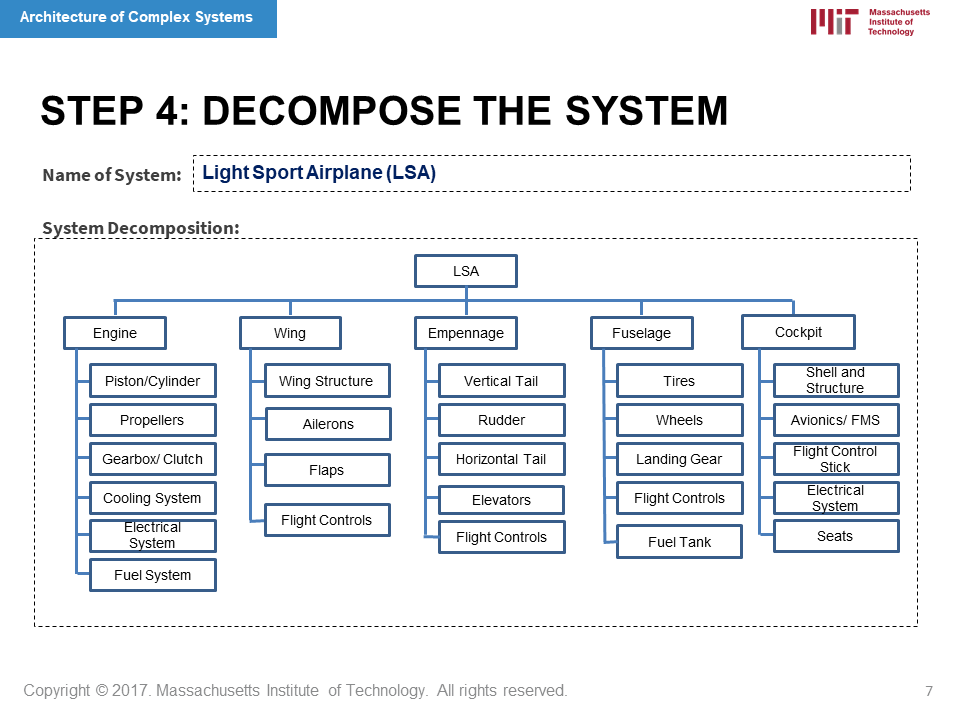

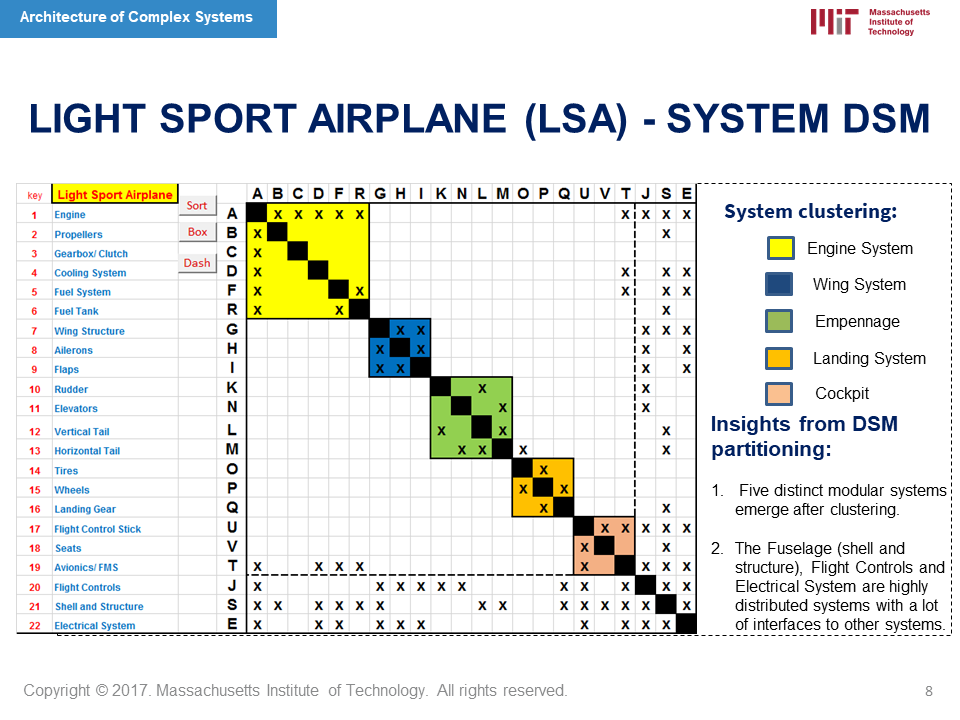

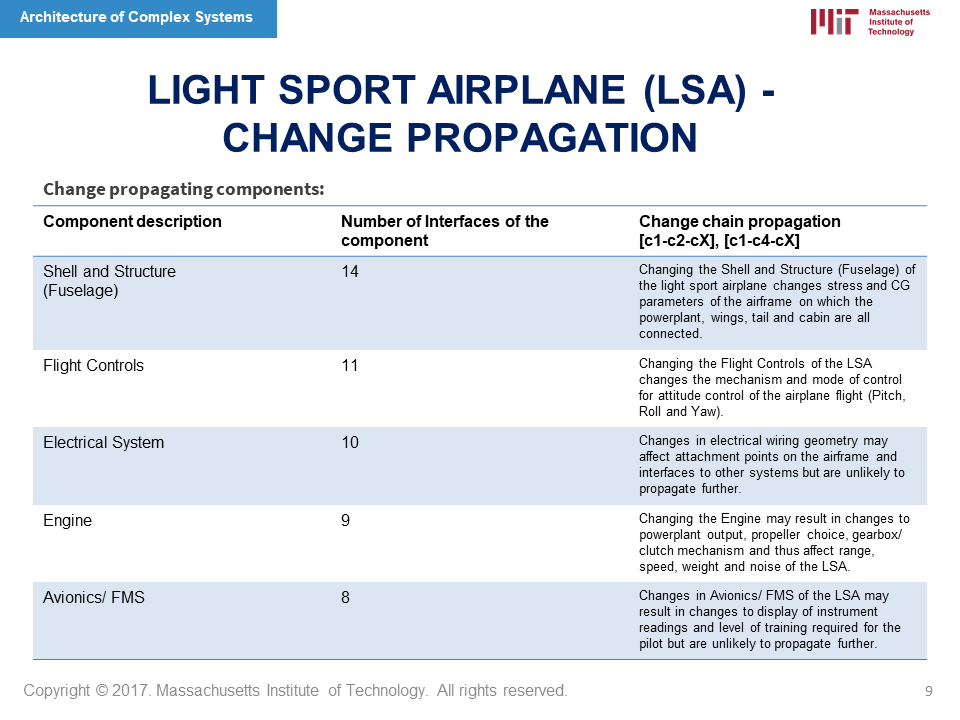

The Design Structure Matrix (DSM) is a network modeling tool utilized to decompose the architecture of a complex technical system and their interactions thereby highlighting the system architecture. The DSM is represented as a square matrix (N x N) mapping the interaction among the set of N system elements. The product architecture DSM provides a highly effective representation of product components and their relationships.

The Domain Mapping Matrix (DMM) is a systems engineering design and management (SDM) tool that allows to develop a top-level QFD (Quality Function Deployment) matrix, mapping customer requirements to product specification. The DMM analysis can help to clarify the relationship between domains and also in verifying the elements comprising each domain.

Modularity is an approach to managing complexity in system architecture by breaking up complex engineering systems into subsystems, connected to each other with well-defined interfaces. Modularity enables firms to take advantage of different approaches to design, manufacture and go-to-market with their products. It also facilitates rapid adoption and dissemination of new technology. Modularizing a system enables platform engineering, in which common core components are grouped together and used in a variety of “derivative” products that have different external appearances of attributes.

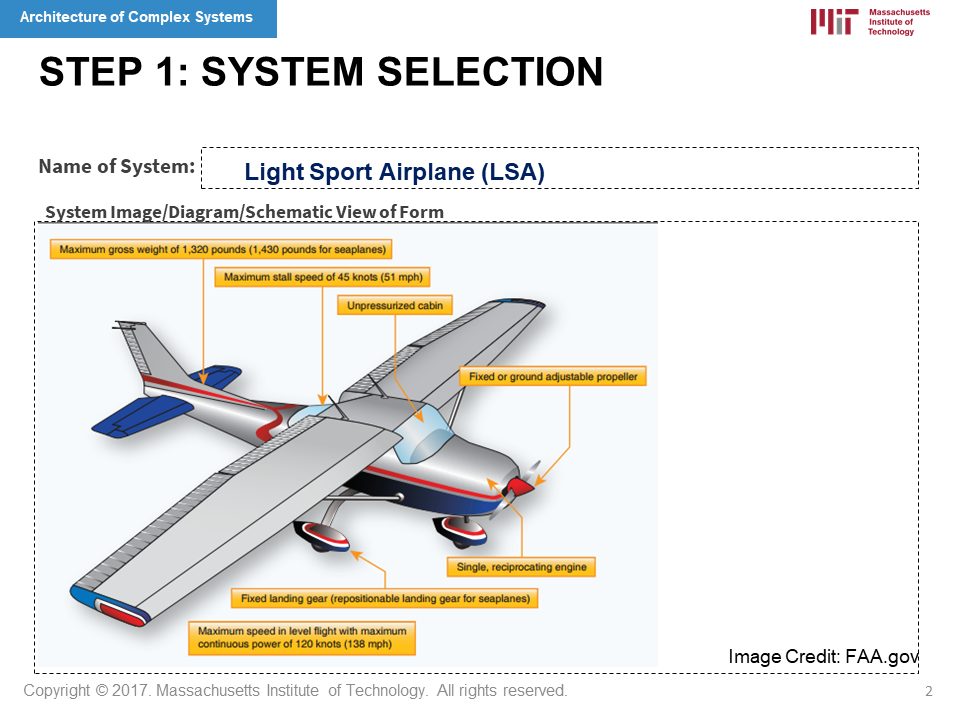

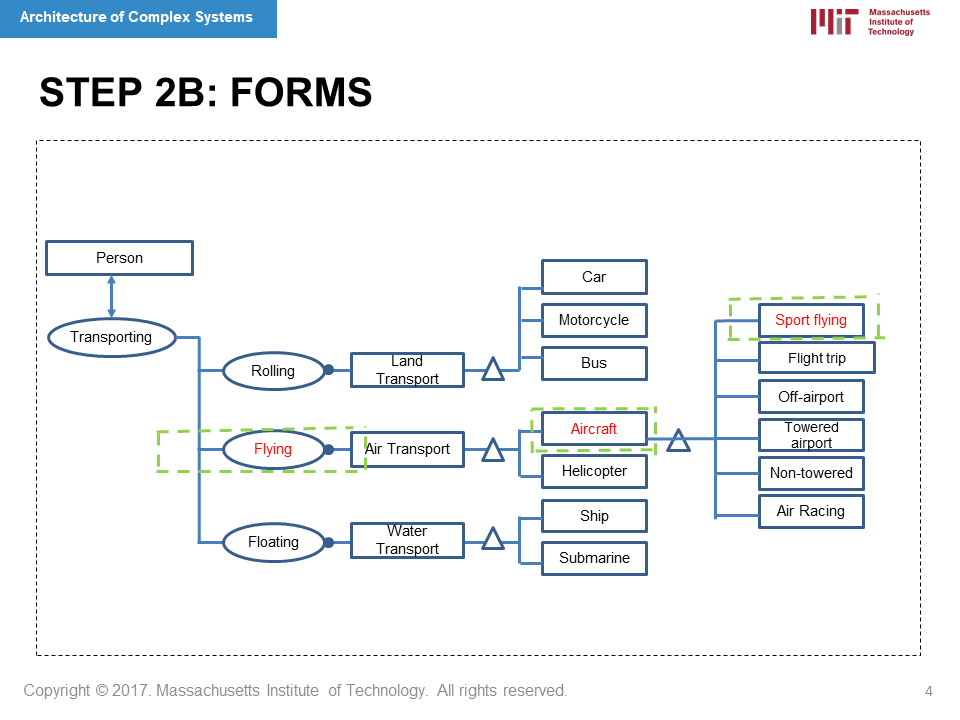

Light Sport Airplane (LSA)

The introduction of Sport Pilot/ Light Sport Aircraft (SP/ LSA) regulations in 2004 by the Federal Aviation Administration (FAA) heralded a new aviation horizon in the United States. The Sport Pilot certificate holders have increased from 134 in 2005 to about 6,500 in 2019. Light Sport Airplanes (LSA) account for 20-25% of all General Aviation piston airplanes sold since 2009.

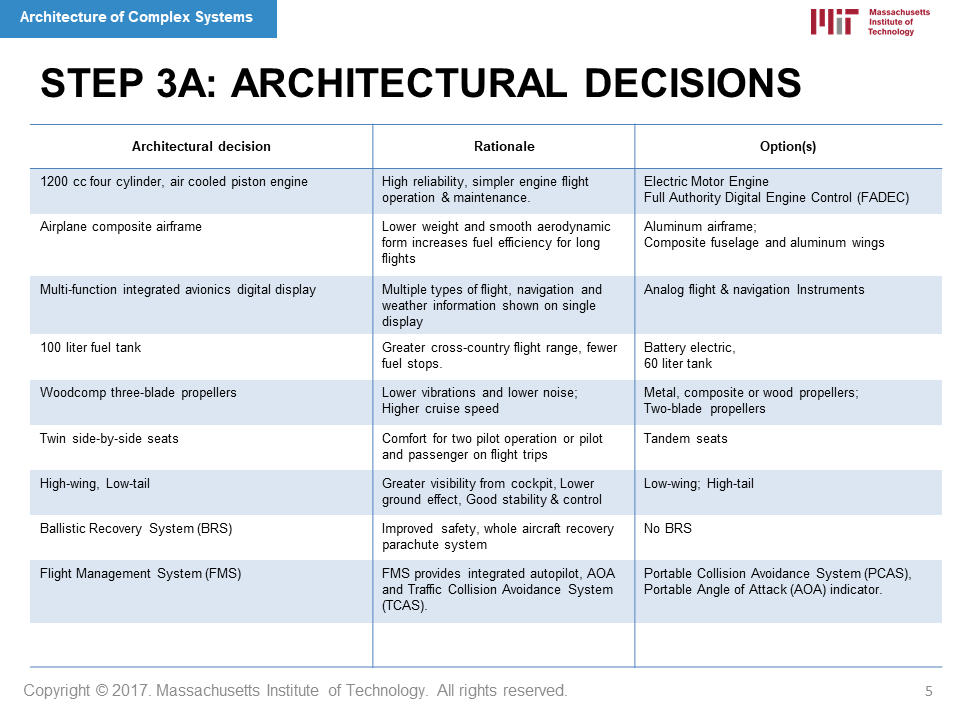

The development of a Special-Light Sport Airplane (S-LSA) follows a typical general aviation airplane design and product development steps though with less stringent FAA testing and certification requirements but in compliance with the ASTM standards. Also, instead of the FAA certificating that a manufacturer meets the standards, it relies on a declarative system whereby a manufacturer presents documentation to the FAA showing that it has complied with FAA regulations and the consensus standards specific to LSA. They also allow government, industry, and consumers to work together to develop standards that will ensure safety without the expense of current aircraft certification rules. This new approach to certification allows for the production of more affordable, safe, and modern factory-built aircraft. The Special-Light Sport Airplanes (S-LSA) utilize state-of-the-art digital avionics given that a FAA certification is not a requirement for this category.

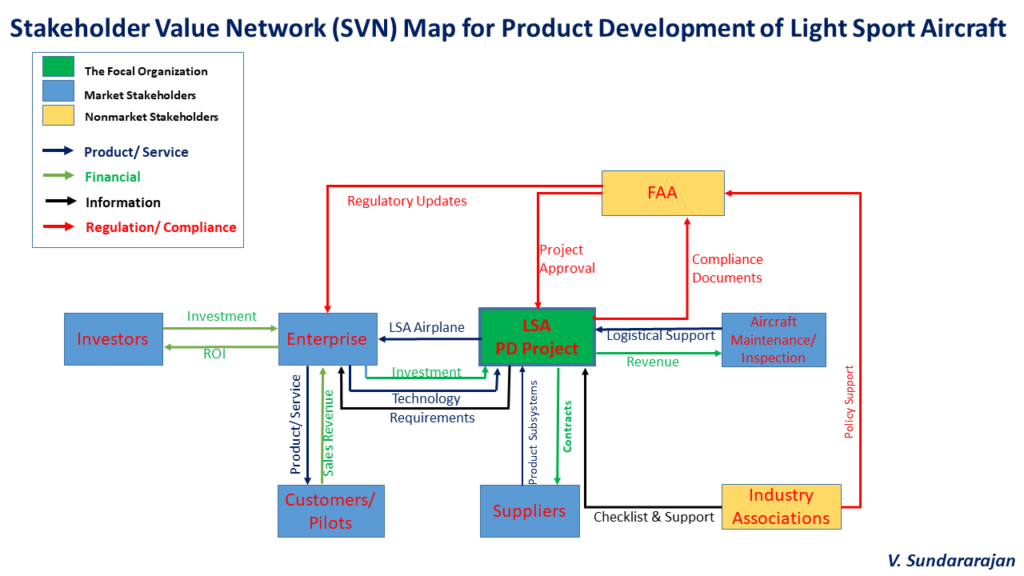

The following high-level stakeholder map shows the qualitative model visualization for a new Special-Light Sport Airplane (S-LSA) product development (PD) project, which includes 17 value flows between 8 stakeholders.